Halogenation

There are two basic types of halogenation reactions:

Substitution Reaction:

In these type of reaction the halogen replaces another atom in the molecule, for example the chlorination of butane

Addition Reaction:

In these type of reaction the halogen reacts with an unsaturated molecule, for example the reaction of chlorine or bromine with alkane or alkene.

Chlorination

Chlorination is the core chemical reaction technology for the products manufactured by SGRL. This applies to various pharmaceutical intermediates and to chlorinated reagents and their derivatives which are used as fine chemicals or in custom synthesis.

For reasons of environmental, health and safety the whole manufacturing activity is carried out in closed systems. All the exhaust gases generated during the chlorination process are either converted to Gaseous or liquid by-products or recycled and returned to the integrated production system.

Customer Benefits:

- Sustainable production processes

- Efficient chlorination processes in batch and continuous processes

- Environmentally friendly recycling of gases generated during the chlorination process

Chlorination with Chlorine

- Carboxylic Acids & Salts

- Carboxylic Acid Esters

- Alkyl and Aryl Chlorides

- Acid Chlorides

Chlorination with thionyl chloride

- Carboxylic acid chlorides

- Chloroalkyl ethers

- Chloroethyl amines

- Sulfonyl chlorides, aliphatic

- Sulfonyl chlorides, aromatic

Chlorination with sulfuryl chloride

- Alkyl and Aryl chlorides

- Carboxylic acid esters

- Sulfonyl chlorides, aromatic

- Sulfonyl chlorides, aliphatic

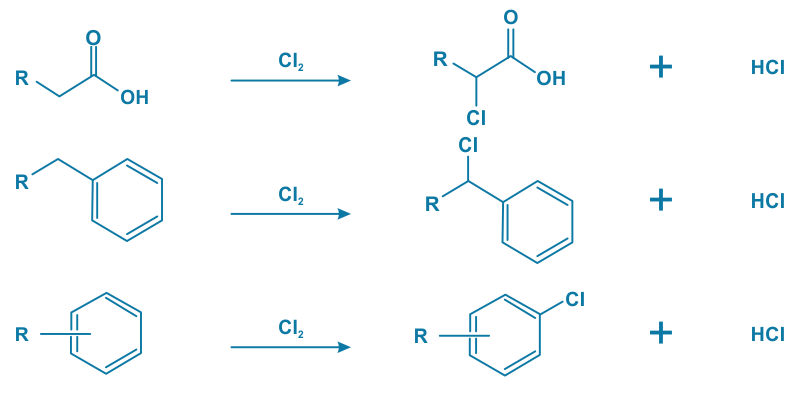

In this reaction technology liquid and gaseous chlorine is used for the direct chlorination of hydrocarbons to carbonyl, benzyl and aromatic chlorine compounds. We perform these type of chlorination reactions in batch or continuous processes, from small scale to large commercial quantities.

Categories of the product made using this reaction technology, please inquire:

- Carboxylic acids and salts

- Carboxylic acid esters

- Alkyl and Aryl chlorides

- Acid Chlorides

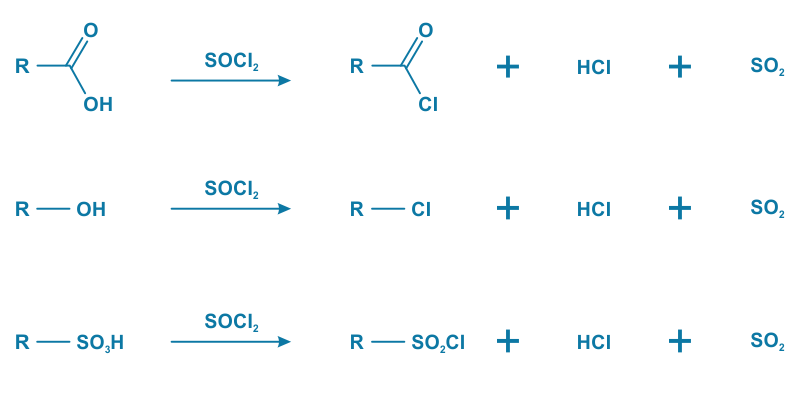

Chlorination of molecules with functional groups such as alcohols, carboxylic acids or sulfonic acids is carried out with thionyl chloride. This produces the corresponding alkyl or aryl chlorides, acid chlorides or sulfonyl chlorides.

Chlorination reactions with thionyl chloride produce HCl and SO2 as exhaust gases. SGRL offers the possibility of customer-specific chlorination within the full integrated system, in which the exhaust gases are either separated, purified and reused as raw materials or converted to Gaseous or liquid by-products. This enables environmental friendly and sustainable production, from pilot plants to large-volume commercial quantities in both batch and continuous processes.

Categories of the product made using this reaction technology, please inquire:

- Carboxylic acid chlorides

- Chloroalkyl ethers

- Chloroethyl amines

- Sulfonyl chlorides, aliphatic

- Sulfonyl chlorides, aromatic

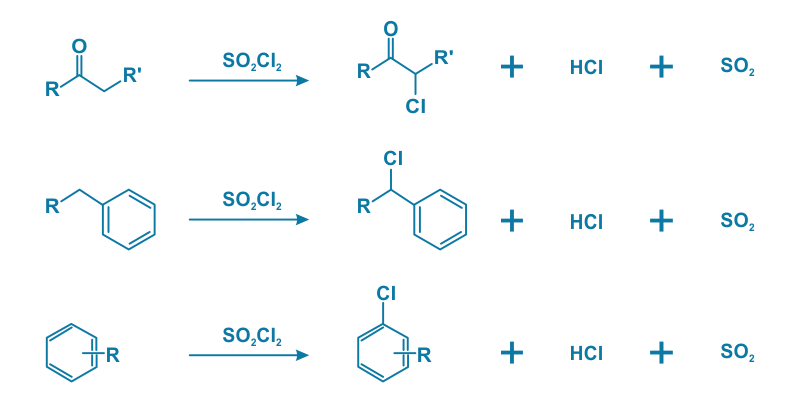

Sulfuryl chloride is an alternative chlorinating reagent to chlorine. It has a more selective effect in the chlorination of carbonyl compounds, benzyl positions and aromatics.

Chlorination reactions with sulfuryl chloride produce HCl and SO2 as exhaust gases. SGRL offers the possibility of customer-specific chlorination within the full integrated system, in which the exhaust gases are either separated, purified and reused as raw materials or converted to Gaseous or liquid by-products. This enables sustainable production, from pilot plants to large-volume commercial quantities in both batch and continuous processes.

Categories of the product made using this reaction technology, please inquire:

- Alkyl and Aryl chlorides

- Carboxylic acid esters

- Sulfonyl chlorides, aliphatic

- Sulfonyl chlorides, aromatic

Bromination

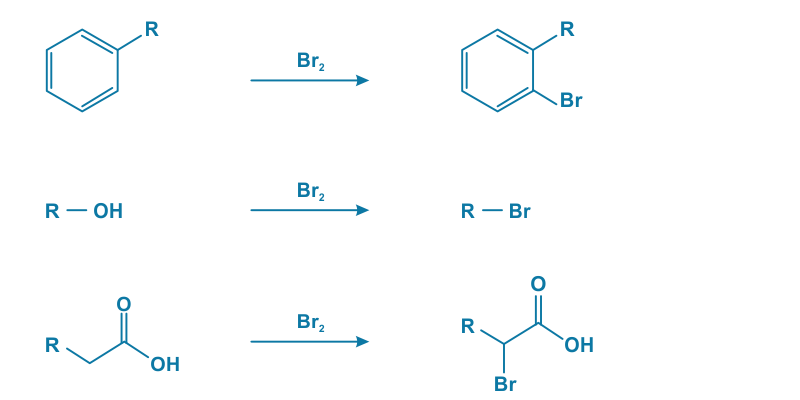

Bromination can be performed either with elemental bromine (Br2) or with bromide salts and mixture of bromide salts and an oxidant, such as hydrogen peroxide.

SGRL also has the appropriate infrastructure and know-how to carry out bromination reactions on a large industrial scale. We operate a dedicated system ranging from storage tanks and piping systems with all the appropriate safety equipment. For reasons of environmental health and safety the whole manufacturing activity is carried out in closed systems.

Liquid and gaseous bromine is used for the direct bromination of hydrocarbons to their carbonyl, benzyl and aromatic bromide compounds. Bromination reactions produce HBr as exhaust gases. SGRL offers the possibility of customer-specific bromination within the full integrated system, in which the exhaust gases are either separated, purified and reused as raw materials or converted to Gaseous or liquid by-products. This enables sustainable and environment friendly production, from pilot plants to large-volume commercial quantities in both batch and continuous processes.

Customer Benefits:

- Sustainable production processes

- Efficient bromination processes in batch processes

- Environmentally friendly recycling of gases generated during the bromination process